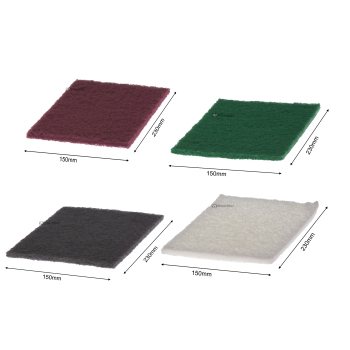

Similar items

57,58 € - 65,04 € *

5,76 € per 1 m

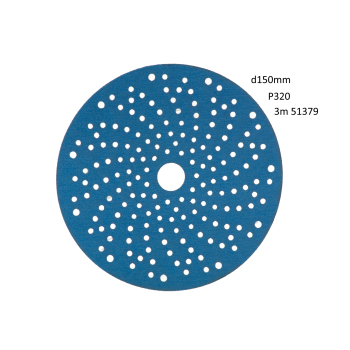

More variations available.

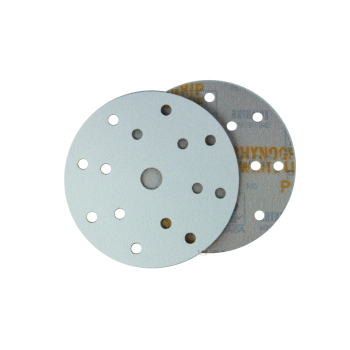

More variations available.

Question about item